Category: Mail: [email protected] green tape, silicone vacuum bag, teflon mesh

for EVA Glass Laminating Machine

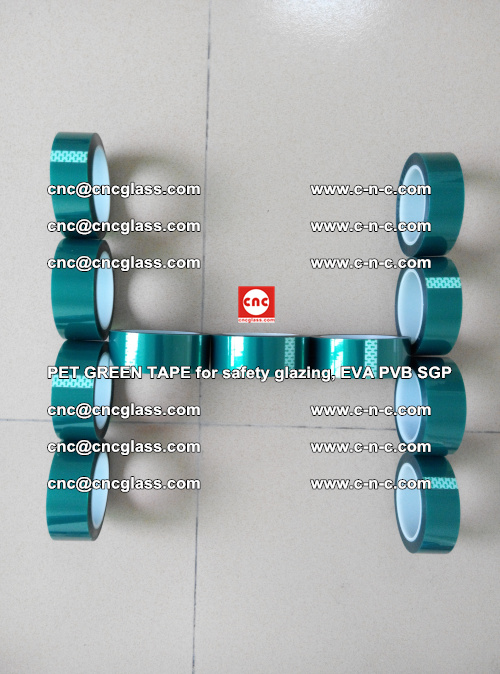

PET GREEN TAPE for safety glazing, EVA PVB SGP

Ethylene Vinyl Acetate EVA Interlayer Film for Laminated Glass

EVA Film:

EVA stands for Ethylene Vinyl Acetate Copolymer, a copolymer resin used in the production of laminated glass as the interlayer film sandwiched between two pieces of glass, like PVB Interlayer Film, and SGP Interlayer Film. The main function of the interlayer is to stick the two piece of glass together, in order to make the sandwiched glass safer and more secure.

EVA Film performs excellent in bonding strength, heat resistance, cold resistance, humidity resistance and tensile strength in laminated glass. It has been partly taking the places of PVB film in laminated safety glass, laminated art glass, and laminated color glass.

EVA film is not adhesive at room temperature. After heating, it melts and has cross-link reaction. In the production of laminated glass with EVA interlayer film, no autoclave, roller press, air bag, or vacuum rubber ring is required. As EVA interlayer Film can be processed under normal climatic conditions, no clean room with climatic control is required in PVB lamination. And the laminating machine line of laminated glass with EVA Film is less cost and easier to install. All laminating processing will be finished and completed in one vacuum laminator. EVA Film for laminated glass has excellent transparency, outstanding adhesion and aging-resistance (more than 15 years), can be used for architectural glass, decorative glass with fabric, privacy glass, auto glass etc.

Advantages of EVA film :

– High tensile strength

– Excellent transparency

– Outstanding adhesion

– UV protection

– High impact resistance

– Good temperature withstanding

– Water proof

– Humidity durable

– Long-term reliable (long-term aging resistance)

– Sound barrier

Names of EVA FILM for Laminated Glass

Some will call EVA Film in different name:

-laminated glass eva interlayer

-ethylene vinyl acetate film

-solar eva film

-glass lamination film

-glass laminating film

-laminating film rolls

-lamination film

-safety glass film

-tempered glass film

-security glass film

-glass eva film

-laminate film

-security laminate film

-decorative glass film

-stained glass film

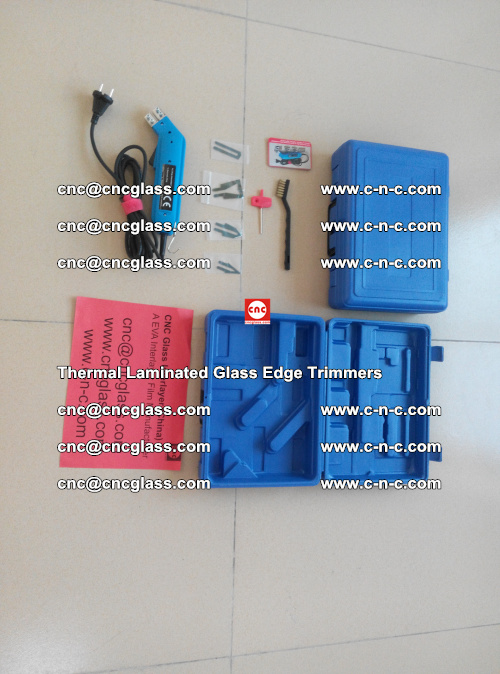

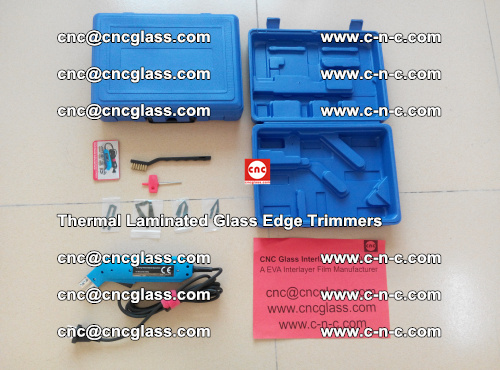

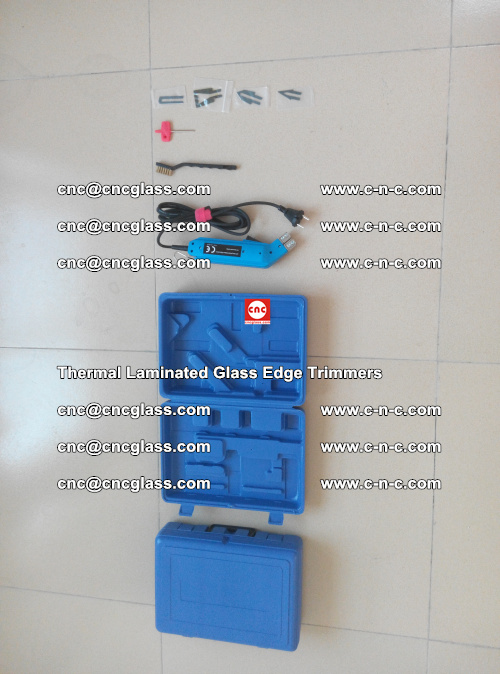

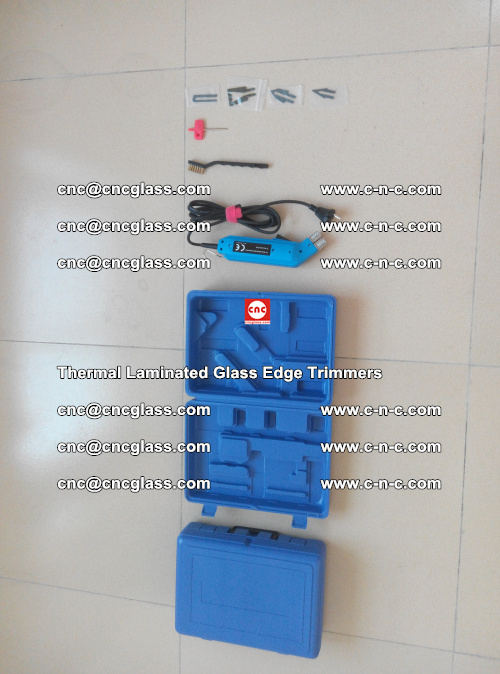

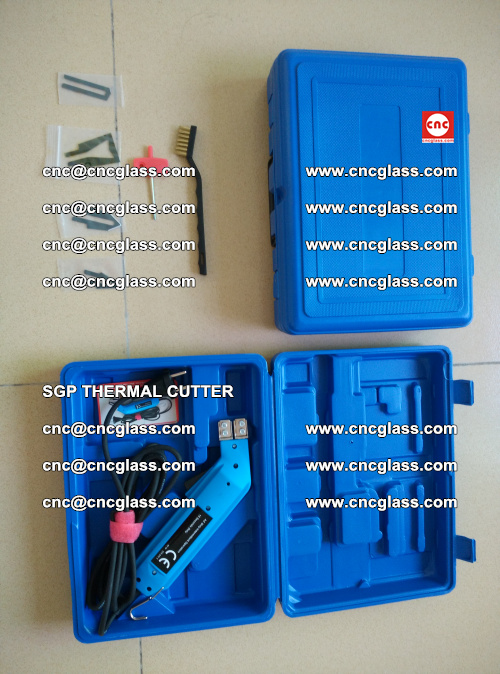

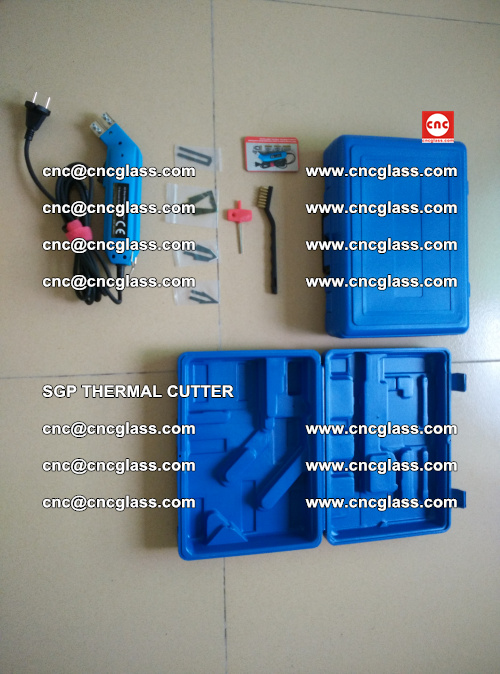

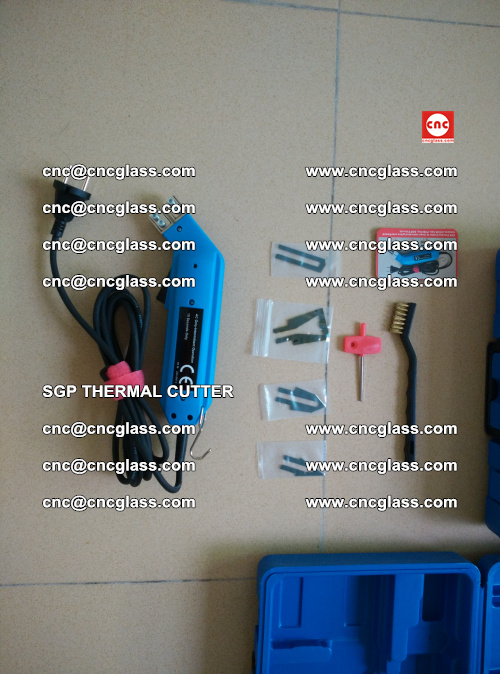

Thermal Laminated Glass Edges Trimmers, for EVA, PVB, SGP, TPU

EVA Thermal Cutter

to clean laminated glass edges overflowed remains of EVA, PVB, SGP etc.

Technical Data:

CE Standard: AC 230V/50Hz

US Standard: AC 120V/60HZ

Power: MAX 90W

Temperature of Blades: Up to 500℃ in seconds

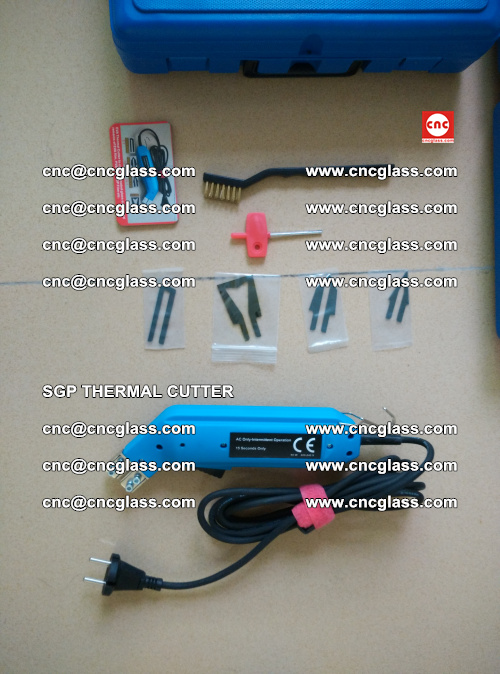

Preparation:

A-Select a Thermal Cutter blade corresponding to the cutting use.

B-Loosen the knurled nut when device is cold.

C-Insert each leg of the blade and tighten the knurled nuts. Make sure that the blade and the cutting head have optimal contact. If both legs of the blade are not properly installed, the unit will not heat up.

D-Power on.

Cutting:

A-Actuate switch, the indicator light and the blade will heat up.

B-Avoid direct short circuit between cutting heads.

C-Do not use metallic rulers for guiding the blade.

D-Clean cutting heads with enclosed wire brush.

E-Please make sure the blade is connected to the cutting material before blade heats up.

Caution:

A-Always operate the Thermal Cutter in well ventilated space.

B-Never burn off the excess residue on the Thermal Cutter blade. The blades will over heated and be warped.

C-Only operate Thermal Cutter when it is in contact with the insulation board

D-Keep hot blades away from skin, clothing and other flammable materials.

E-Allow blades to cool before handling. Thermal Cutter may cause injury or burns to exposed surfaces.

F-The Thermal cutter is working intermittently, that means If the temperature inside the tool is too high, the unit will get hot and the internal thermal protectors will turn off automatically, after it cool, the Thermal Cutter will operate again.

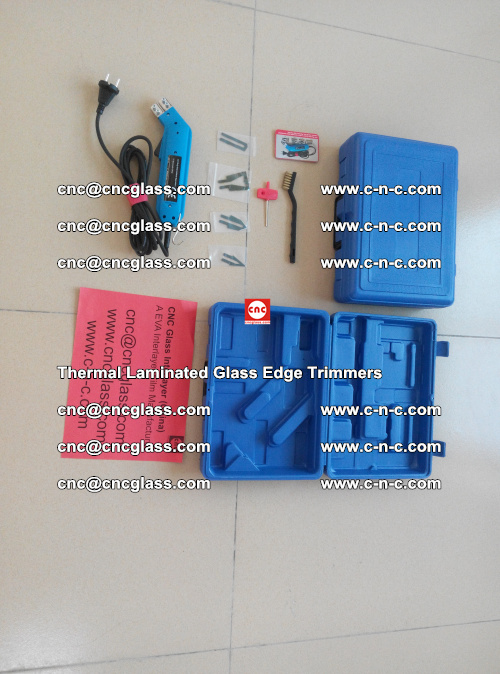

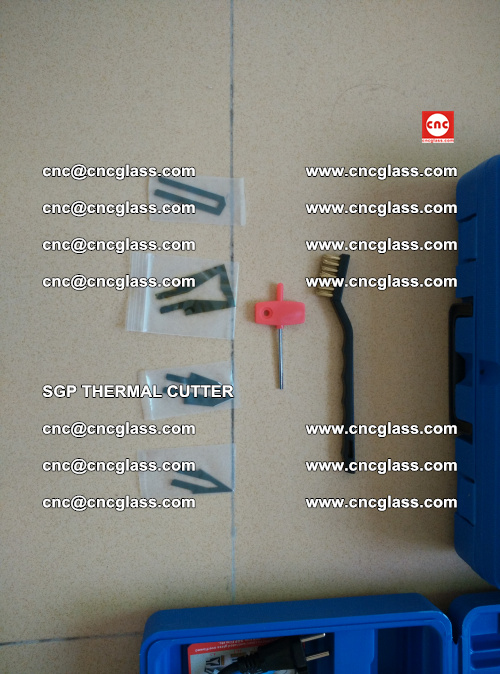

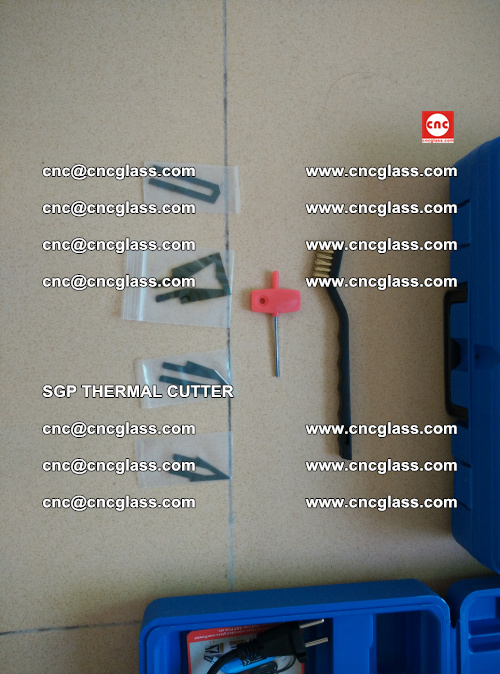

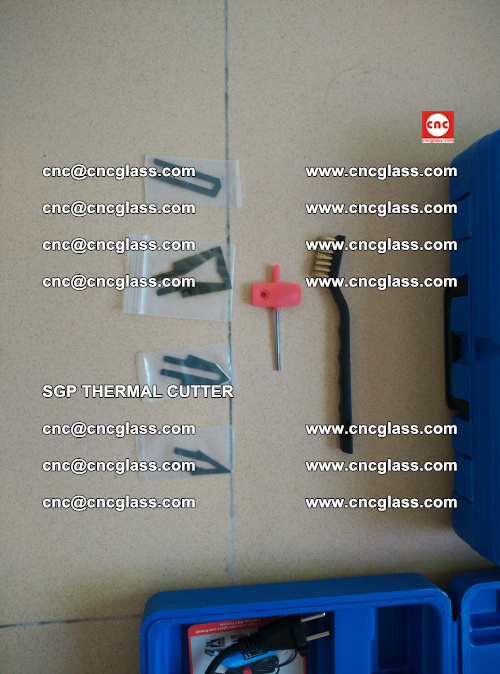

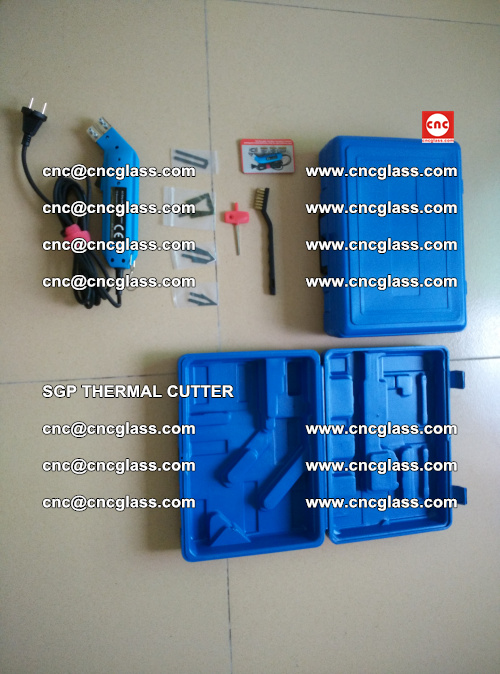

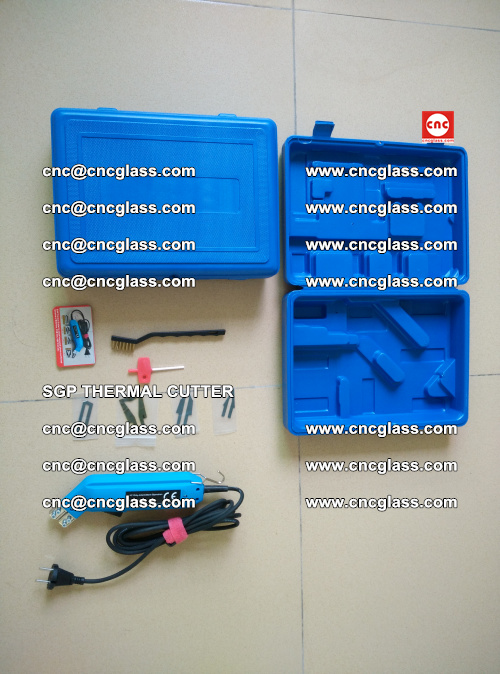

SGP THERMAL CUTTER, cleaning safety laminated galss edges

EVA Thermal Cutter

to clean laminated glass edges overflowed remains of EVA, PVB, SGP etc.

Application:

When making laminated glass with EVA film(or PVB film, SGP film) there may be some overflowed EVA remains (or PVB remains, SGP remains) on the edges of laminated glass after heating in the oven, EVA Thermal Cutter is the handhold tool to clean the laminated glass edges remains easily.

How it work:

The blade of the EVA Thermal Cutter can be up to 500℃ in seconds. The EVA Thermal Cutter use the ultra high temperature heat to cut the EVA remains (or PVB remains, SGP remains) of the laminated glass edges.

The EVA Thermal Cutter cleans the overflowed remains NOT by strength or sharp, but by Ultra High Temperature Heat: 500℃. So whether the interlayer film is EVA FILM, PVB FILM, or SGP INTERLAYER, the result is the same.

Data:

CE Plug: AC 230V/50HZ

US Plug: AC 120V/60HZ

Temperature of Blades: Up to 500 ℃ in in approx 5-7 seconds

Thermal Cutter is available in 4 shapes of blades to remove the remains of laminated glass edge.

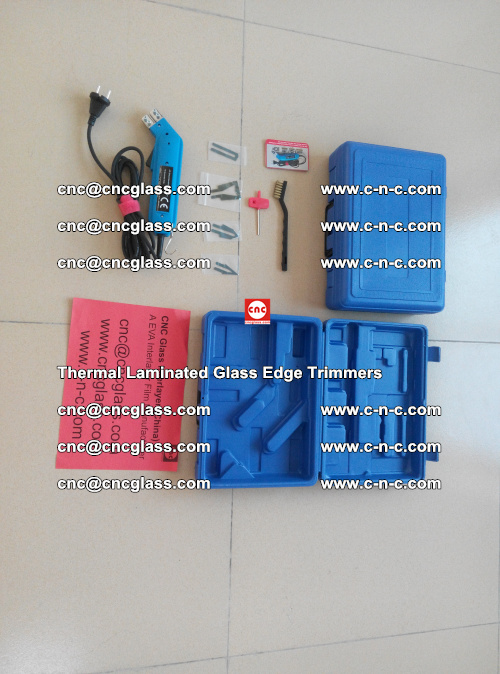

Comments from Our Clients:

*Comment1:

Peter,

The Thermal Cutters were received 10/9, in the afternoon. I have already used them and they work great. Much better than the method I was using before.

*Comment2:

Dear Olivia,

My people are very happy with the cutting tool.

*Comment3

Peter,

Yes, we received the cutters. We have already been using them and they work very nicely.Thank you for your help.

*Comment4

Dear Olivia,

We have good result with EVA thermal cutter, my colleague will contact you to place new order.

CNC Glass Interlayer

www.cncglass.com www.c-n-c.com

[email protected] [email protected]

Product 1]Super Clear EVA Film for safety laminated glass

Product 2]Milky White EVA Film for safety laminated glass

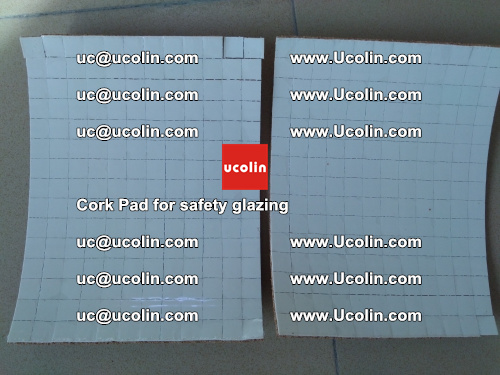

Product 3]Green Tape and Thermal Cleaning Cutter for EVA film safety laminated glass glazing